Reliably lead galvano telescopic technology to long-term success

Galvano prosthetics are held in the highest regard. Their reputation precedes them. You could already describe them as the legend of high-end restorations. Titanium and gold are therefore two excellent elements to ensure permanent use in the oral cavity. They resist chemical forces and are therefore important pillars of galvano technology – they are one of the strengths of this procedure. Even precious metal free alloys for the accompanying model casting and/or the metal base can be described as a good and technically correct choice. Below, MDT Wolfgang Bollack speaks in favour of galvano technology, which allows patients with few teeth to be rehabilitated with firm feeling teeth and demonstrates the correct way. He even goes into the potential dangers and preconceptions of galvanism, which he substantiates with the keyword “myths”.

When I discussed the great advantages of galvano telescopic technology in the area of removable implant dentures with new customers in the past, I frequently got one of two reactions. On the one hand: “oh, they lose their friction so quickly!”, and on the other hand: “Galvano technology is said to lead to galvanism in the mouth. There is that article by Prof. Niedermeier of the University of Cologne about galvanism in the mouth, where galvano telescopic technology comes out badly” [1, 2] In this article, Prof. Wilhelm Niedermeier even said that galvano technology was a biological backwards step, which greatly unsettled the professionals.

Completely unjustifiably as we now know from years of laboratory and practical experience. In my report, I would now like to talk about galvano technology from our 25 years of experience and take a stand on the above arguments and fears.

The basic characteristics of long-term success

One thing is very important to me: if you are dealing with galvano telescopic technology, you must know its limits and weaknesses, which forms of restoration it is best used in, and where it is unsuitable.

Increased space requirements can be a problematic topic for example, which is why we only use galvano telescopic technology in the area of removable implant restorations. A titanium abutment can be made more delicate than a natural tooth, because you need 3 elements per connecting element: a primary part and/or abutment, a secondary part (galvano crown) and a tertiary framework, usually made from a CoCr alloy. Therefore, this technology does not work in the anterior mandible on natural teeth at all.

With combined restorations, i.e. natural teeth and implants, we always produce normal 0° telescopic crowns made of a precious metal free alloy for the natural tooth stumps and 2° and/or 4° milled abutments for galvano crowns on implants. As a rule, 2° millings are recommended for abutments, particularly if screw channel openings are located on the milled surfaces. Yet, with our technology without conductive silver lacquer, the galvano crowns often have a very firm hold, meaning that many patients have a problem removing the implants from their mouths. According to the number and

distribution of the abutments, we frequently carry out 4° millings.

Knowledge of the ductility of 24-carat gold is another important point in galvano technology. On the one hand, this ductility has the big advantage that galvano copings can fit the titanium abutments even better, even after sticking into the mouth, due to cold forming, and therefore, contribute to even higher precision and permanent friction. On the other hand, this possibility of cold forming also brings a disadvantage. It means that the galvano copings can bend easily, which can lead to loss of adhesion in some circumstances. Therefore, galvano secondary parts must always be given a stable enclosure with the tertiary framework.

Furthermore, galvano works must also always contain a sufficient support polygon. In the lower jaw, usually 4 implants in the area of the 2’s, 4’s or 5’s are sufficient, depending on the location of the mental foramen. In the maxilla, due to the softer bones, 6 implants should always be used, preferably in the area of the 1’s, 3’s, 5’s and/or 6’s, according to the bone available and/or location of the maxillary sinus. A square but always at least triangular support should be aimed for. Constructions with a short lever arm (i.e. resistance leverage) and long lever arm (i.e. engaging lever), e.g. in the lower jaw for interforaminal implants, or generally in unilateral fixtures, are not suitable for galvano technology.

Dentists’ first fear mentioned above, that the “friction does not last long”, is the easiest to confront. This is clearly a manufacturing problem, where it should be clearly criticised that the error lies with the work instructions of the galvano system providers, as the use of conductive silver lacquer is always recommended here. This instruction comes from the times when galvano crowns were produced from plaster die: however, it is unnecessary for use on titanium abutments and even harmful for the inner surfaces of the galvano copings.

Note: Conductive silver lacquer should not be used on titanium abutments in the scope of implant restorations.

If you apply conductive silver lacquer to a high-gloss polished titanium abutment, a separation gap of approx. 5-25 ?m will form. Please note this phenomenon and proceed appropriately! Without conductive silver lacquer, there is no separation gap and the galvano coping can be separated from the titanium abutment without any problem. However, the conductive silver lacquer also leads to another problem: a rough surface. Accordingly, the inner surface of the galvano coping is also rough, which is why the galvano crowns look silk-matt on the inside. Many galvano users believe this to be normal. However, if you looked at this inner surface under a scanning electron microscope, it would look like a crater landscape or an alpine panorama, where ultimately only the mountain tops remain, but in turn wear mechanically relatively quickly, meaning that the hydraulic effect is lost eventually. The inner surface of a galvano crown must be high-gloss after galvanisation, i.e. the “negative” of the polished titanium abutment. Because only then is it guaranteed that the adhesion and/or friction is retained for a lifetime.

As shown in fig. 1 and 2, the conductive silver lacquer must not be applied to the functional surfaces, but only occlusal to close the screw channel, and at the edge as a conductor for the cathode. Fig. 3 shows the result without conductive silver lacquer in the previous manufacturing process – a high-gloss inner surface of the galvano coping.

It is for precisely this reason that you should not manufacture galvano crowns on gold abutments and/or primary parts, and on zirconium dioxide abutments and/or primary parts. Here, conductive silver lacquer is always required for the whole surface, which destroys the high-precision galvano technology.

At this point I would like to point out, it is frequently said that galvano crowns only hold in the mouth due to the saliva in the mouth. I cannot confirm this based on our 25 years of experience. This is a pipe dream, because a galvano crown that does not hold in the laboratory, will not hold better in the mouth. Still, the saliva does increase the capillary effect.

On the question of galvanism in the patient’s mouth

Now, back to the article of Prof. Niedermeier, and the second fear expressed by dentists that galvano technology in the mouth leads to galvanism. Certainly, Prof. Niedermeier’s article contains many correct analyses and experimental results that are important for science. It is also a well-known problem that placing different alloys next to each other in the mouth can lead to galvanism, especially if alloys with a high gold content come into contact with amalgam, or if economy gold alloys, silver-palladium or copper-palladium alloys are used.

The problems this can cause for the whole body have been well investigated and documented. The best way to prevent the problem is to keep to the least possible elements. However, it is only a suspicion and/or an assumption that galvano technology also brings such risks, and only because there are very high differences in potential between the materials used. Unfortunately,

Prof. Niedermeier’s article does not provide any long-term studies on the actual effects of this material combination.

Without knowing about this article, we have been able to achieve the best results with this technology for over 25 years. Over time, even older galvano works have come to us in-house, because we have had to replace denture teeth and veneers. In all of these works, the galvano crowns still looked like they did on the first day and were still functioning impeccably. If there had been relevant galvanic currents and ion migrations, you would have expected to see at least slight changes to the galvano copings.

However, that is not the case, as you can clearly see e.g. in fig. 4 and 5. This is work that has been in the mouth for many years. Until now, my customers have never reported a metallic taste or allergic reactions in patients. On the contrary, the patients are full of praise for the perfect fit and high wearing comfort.

Of course, I don’t want to negate the topic of galvano currents in the mouth, because they exist. But by all appearances not on galvano telescopics on titanium abutments, because the reality after 15-20 years shows a different picture. However, I am not a

scientist but a dental technician. I don’t know whether and to what extent ion migration occurs, however I can tell whether there have been changes to galvano secondary parts after

fessional denture clean and polish. The man has taken pretty good care of his denture. Please note: In some patients, more plaque can be observed around the denture teeth, which of course is also to do with dietary habits. However, after such a long period of wear, this image is completely normal, which is why we professionally refurbish them in the laboratory from time to time.

However, the galvano crowns are still in an impeccable condition. We can’t find any plaque, no metal deposits and no wear.

The following work has also been in the mouth for approx. 16 years (fig. 5a-d). The patient came to us because part of the denture border was broken. She has excellent oral hygiene and impeccable denture cleaning. Here too, most of the galvano crowns look like they did on the first day. Only one of them had a little plaque on it. Yet the function is perfect, and the patient is still impressed with her denture. And the most important thing: no sign of periimplantitis in either implant!

After a wealth of experience with many impressed practitioners and patients, and based on our convictions, we can safely say that the galvano technology is the most successful form of restoration for removable dentures on implants. All of our customers who have used this technology as a treatment method for many years confirm this.

Current case study from our laboratory

On fig. 6a-g it is clear to see how not to carry out galvano work. This denture, carried out alio loco, was only in the patient’s mouth for THREE! Years, when he came into the laboratory for a replacement. It had not held right from the start, and soon had to be replaced and/or extended with locators. Such incorrect execution continually leads to galvano technology falling into disrepute – whereas it is actually a wonderful treatment method when used correctly!

Fig. 6a-c document the front positioned too far towards the labial. Fig. 6d shows the maxillary denture with the insufficient galvano secondary parts and the extended locator retention

Fig. 6d: Insufficient galvano secondary parts in the maxilla.

Fig. 6e: Secondary parts welded too loosely in the lower jaw.

Fig. 6f and g: The static and tilting torque were not considered for the front teeth; the aesthetic leaves a great deal to be desired.

elements, with which the restoration was able to be held in the first place. We have a similar picture in front of us in the lower jaw, with secondary parts welded too loosely, made of a gold alloy in the 4th quadrant, and also locator retention elements in the 3rd quadrant. Also, with regards to the aesthetic in the patient’s mouth, the protruding front teeth were immediately noticeable (fig. 6f and g). Very little consideration was given to static and tilting torque here, and overall, this is not a glorious moment for German dental technology.

How did we approach this case? We took the original occlusion from the copy of the existing dentures, available from the dental practice. Then, we produced a new denture wax try-in, with a significantly recessed front and slightly individualised front tooth position. The denture wax try-in was our suggestion, which was tried in the practice (fig. 7a-f).

After the denture wax try-in was approved, it then formed the basis for all further work steps (fig. 8a-c).

After the aesthetic check in the mouth and small corrections, we initially approached the digital planning of the individual abutments.

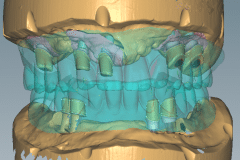

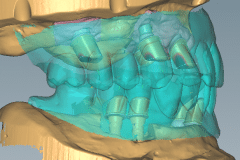

To this end, the denture wax try-in was scanned (fig. 9a and b) and this was followed by the virtual planning of the abutments (fig. 9c and d)

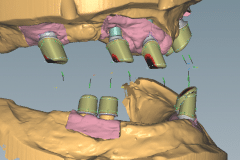

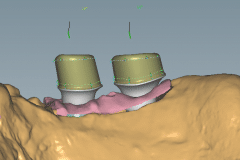

with the subsequent execution in titanium (fig. 10a-d).

After years of observations and retrospective examinations of some of my customers, it transpires that fixed implant restorations, especially with attached pink ceramic, lead to periimplantitis significantly more often than removable restorations. This is due solely to the poor cleanability of the fixed implant restorations.

Yet, even with removable galvano works, periimplantitis can develop. Due to the direction of insertion from the front, there are occasionally severe distal overhangs in terminal abutments. If these overhangs are too close to the gingiva, patients have problems cleaning them thoroughly. This leads to plaque deposits, which can then also lead to periimplantitis. That is why with overdentures we design our abutments similarly to pile dwellings, so that the gingival edge of the milled surface of the abutment is approx. 1-2 mm above the gingiva (see fig. 10a-d). Therefore, the cleanability of the titanium abutments is significantly improved.

Then, the galvano copings (fig. 11a-c) and the model casting framework (fig. 12a-c) is produced. In doing so, it should be ensured that the tertiary framework around the galvano copings is not too tight. There should be a space of around 0.5 mm so that the adhesion process in the mouth can occur in a completely tension free situation. This process sets all micro inaccuracies from the whole manufacturing process, which arise from the various material components and their expansion and/or contraction to 0.

This process makes the galvano technology superior to all other procedures. An occlusal stop must be built into the tertiary framework which holds the galvano copings in place during gluing.

From our denture wax try-in, mock-ups are produced on the framework (fig. 13a-d), which guarantees the correct transfer of the aesthetic try-in onto the metal framework. Because, after gluing in the galvano crowns, new impressions and models will be produced, as the denture wax try-in made on the implant master models can no longer be used.

Now comes the most important phase in the workflow of the galvano technology: the final insertion of the titanium abutments and the gluing of the galvano crowns. According to the Weigl concept, the abutments should not be removed after gluing in the galvano copings. This is because screwing and unscrewing the abutments can lead to minimal deviations, which will reduce the high-precision fit of the galvano crowns. With the frontal mock-up, the aesthetic can now be checked again, and corrected if necessary. This information then forms the basis for the completion of the denture.

After insertion of the abutments, an interim restoration must be available for the transition period, i.e. until the final denture is complete (fig. 14a-d), which can later serve as a travel denture. This is produced directly on the implant master model over the titanium post, using classic denture plastic. We have developed a quick, rational and therefore cost-effective procedure for this. The contact areas of the plastic base of the abutments are covered in silicone in the laboratory. This means that it glides gently onto the abutments and still has a secure hold.

From this point on, our patient was fitted with a functioning and aesthetically pleasing denture again (fig. 15a-c) and was able to dispense with his old dentures. That was a really joyful day for him after a long time suffering with a defective denture.

In the meantime, we are finishing the final denture. After gluing the galvano crowns into the mouth, a bite registration will be carried out to secure the result, and as a later possibility for checking (fig. 16a-d). In addition, new impressions will be produced using the frameworks, new models will be created in the laboratory and these will be mounted in relation to the skull.

Then, a new denture try-in will be made on the frameworks (fig. 17a-d) using the information from the mock-up and the aesthetic try-in.

Then, everything will be executed in plastic (fig. 18a-c).

The comparison with the old restoration makes the progress clear to the patient (fig. 18d-f and 19a-d).

In the earlier denture there were cast gold secondary parts in the 4th quadrant, which hardly had any friction, and makeshift locator retention elements in the 3rd quadrant. Now, the new base is much more delicate, the galvano crowns are high-gloss and have a really firm hold. The change is also visible in the lower jaw: the new denture shows high-gloss galvano crowns, that also have a stable hold.

In the end we did it once again: we made someone happy and conjured a beautiful smile onto their face (fig. 20a-c). That is worth any amount of effort.

My aim was to convince many colleagues of this high-precision technology with this report. You don’t need to worry about the Evaluations

To back up the findings, I would like to quote two very experienced implantologists from my clientele, who use galvano technology in their practices, just as I do in my laboratory.

“myths” or potential dangers of galvano technology. Because they really are just myths, comparable to traditional poems, legends, tales or fabulous stories. Our daily reality shows a completely different picture: the galvano technology is a valuable asset to the patients and we can master it successfully!

Conclusion

Galvano technology provides excellent protection against periimplantitis, with removable and yet secure works in implant dentures.

It is the best method of getting various implant types, sizes and directions in a uniform overall insertion direction, with a defined cone angle.

Thanks to the tension free gluing of the galvano crowns in the patient’s mouth, they offer the highest wearing comfort and maximum precision in the supraconstruction, which provides the best long-term results.

Galvano works also impress with an excellent reparability. Worn denture teeth and veneers can easily be replaced. If an abutment is lost, the best possible periodontal support is still retained.

In our experience from 25 years of work, we have not observed galvanism in the mouth caused by galvano technology.

Literature references:

[1] Niedermeier W: Oraler Galvanismus – Ursachen und Folgen. [Oral galvanism – causes and consequences] ZWR 2015; 124 (12): 578-584. Wissenschaft – Umweltzahnmedizin [Science – environmental dentistry]. Georg Thieme Verlag KG Stuttgart, New York. DOI: 10.1055/s-0035-1569258

[2] Niedermeier W: Regelversorgung im Spiegel der Biokompatibilität. 42. Jahrestagung der Arbeitsgemeinschaft Dentale Technologie 2013. Kurzreferate 2013 [Standard care in the mirror of biocompatibility. 42nd annual conference of the work group for dental technology 2013. Short lectures 2013]: 96-103. www.ag-dentale-technologie.de/wp-content/uploads/2016/03/ADT_Kurzreferate_2013.pdf